بيٽري ٽيڪنالاجي جي مسلسل ارتقا پذير منظرنامي ۾، صحيح ويلڊنگ مشين ڳولڻ موثر ۽ اثرائتي پيداوار جي عملن لاءِ اهم آهي. اسٽائلر، ويلڊنگ ٽيڪنالاجي ۾ هڪ اڳواڻ، هڪ حد پيش ڪري ٿوٺهيل حلمختلف بيٽري جي قسمن ۽ پيداوار جي گهرجن لاءِ. هن جامع خريد ڪندڙ جي رهنمائي ۾، اسان توهان کي چونڊڻ ۾ مدد لاءِ اهم غورن ذريعي نيويگيٽ ڪنداسينڀرپور ويلڊنگ مشينتوهان جي ضرورتن لاءِ.

1. بيٽري جو قسم طئي ڪريو

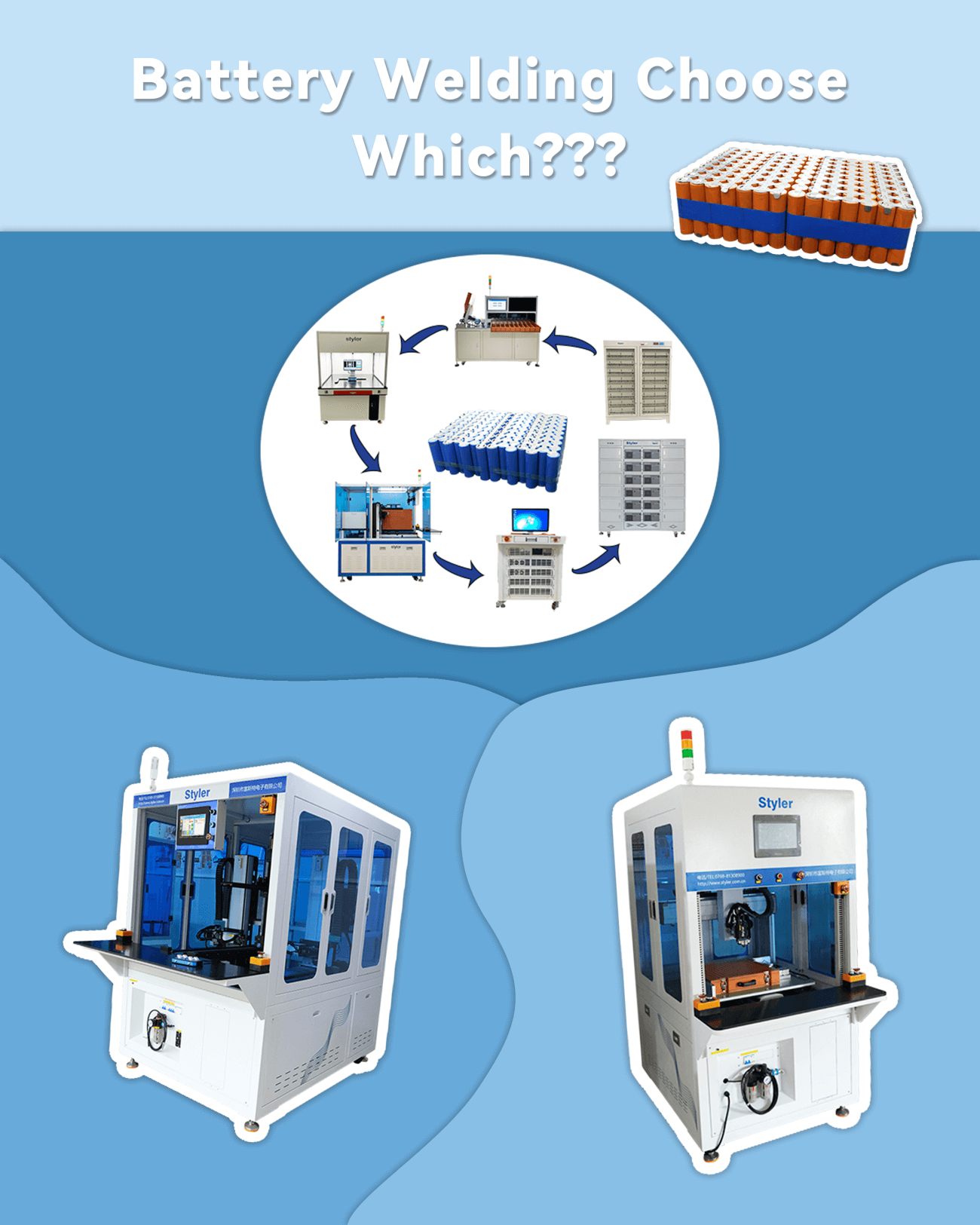

ويلڊنگ مشينن جي دنيا ۾ وڃڻ کان اڳ، اهو ضروري آهي ته توهان ڪهڙي قسم جي بيٽرين سان ڪم ڪندا. ڇا اهو سلنڈر، پرزميٽڪ، يا ٻيا خاص فارميٽ هجن، اسٽائلر وٽ هر هڪ جي منفرد گهرجن کي پورو ڪرڻ لاءِ ٺهيل حل آهن.

2. ويلڊنگ مواد جي تصديق ڪريو

مختلف قسمن جي بيٽرين کي بهترين ڪارڪردگي لاءِ مخصوص ويلڊنگ مواد جي ضرورت هوندي آهي. سلنڈرڪ سيلز لاءِ، 0.1 ملي ميٽر کان 0.5 ملي ميٽر تائين نڪل پليٽ ٿيل يا خالص نڪل پٽيون عام طور تي استعمال ٿينديون آهن. ٻئي طرف، پرزميٽڪ سيلز اڪثر ڪري 1 ملي ميٽر کان 3 ملي ميٽر ٿلهي تائين ايلومينيم ٽيب استعمال ڪندا آهن. اسٽائلر جون مشينون انهن مواد کي درستگي ۽ اعتبار سان سنڀالڻ لاءِ ليس هونديون آهن.

3. پيداوار جي پيداوار جو جائزو وٺو

پيداوار جو مقدار صحيح ويلڊنگ مشين جي چونڊ ۾ اهم ڪردار ادا ڪري ٿو. گهٽ حجم واري سلنڈرڪ سيل جي پيداوار لاءِ، اسٽائلر جي PDC/IPV/IPR دستي ويلڊنگ سيريز لچڪ ۽ ڪنٽرول فراهم ڪري ٿي. وڏي حجم واري پيداوار لاءِ، اسٽائلر جي XY خودڪار سنگل رخا يا ڊبل رخا ويلڊنگ مشينن تي غور ڪريو. ڪسٽمائيزيشن آپشن جهڙوڪ روٽري هيڊ ۽ فڪسچر توهان جي بيٽري جي سائيز مطابق ٺاهيل ڪارڪردگي ۽ ٿرو پُٽ کي وڌيڪ وڌائين ٿا. پرزميٽڪ سيل ويلڊنگ لاءِ، اسٽائلر جون گينٽري گيلوانوميٽر ليزر ويلڊنگ مشينون 1000 کان 6000 واٽ تائين پاور آپشن پيش ڪن ٿيون، مختلف ٽيب مواد ۽ ٿلهي سان مطابقت کي يقيني بڻائين ٿيون.

4. پيڪ اسيمبلي حل ڳوليو

ويلڊنگ مشينن کان علاوه، اسٽائلر نيم خودڪار ۽ مڪمل طور تي خودڪار پيڪ اسيمبلي لائن ڪسٽمائيزيشن سروسز پيش ڪري ٿو. اسان جي وقف آر اينڊ ڊي ٽيم توهان سان ويجهي سان ڪم ڪري ٿي ته جيئن اسيمبلي لائن حل ڊزائين ڪري سگهجي جيڪي توهان جي گهرجن، بجيٽ، ۽ جڳهه جي پابندين سان مطابقت رکن. تصور کان وٺي عمل درآمد تائين، اسٽائلر توهان جي بيٽري پيڪ جي پيداوار جي عمل کي منظم ڪرڻ لاءِ جامع مدد فراهم ڪري ٿو.

صحيح ويلڊنگ مشين چونڊڻ بيحد ۽ ڪارآمد بيٽري جي پيداوار حاصل ڪرڻ لاءِ اهم آهي. اسٽائلر جي مختلف قسم جي بيٽري جي قسمن ۽ پيداوار جي مقدار جي مطابق حلن جي مختلف رينج سان، توهان اعتماد سان پنهنجي پيداوار جي صلاحيتن کي وڌائي سگهو ٿا. ڇا توهان هڪ ننڍي پيماني تي آپريشن آهيو يا هڪ صنعت جو وڏو، اسٽائلر وٽ توهان جي ويلڊنگ جي ضرورتن کي پورو ڪرڻ لاءِ ماهر ۽ ٽيڪنالاجي آهي. بيٽري جي پيداوار ۾ بهتر پيداوار ۽ معيار جي سفر تي شروع ڪرڻ لاءِ اڄ ئي اسان جي ٽيم سان رابطو ڪريو.

پاران مهيا ڪيل معلوماتاسٽائلرتيhttps://www.stylerwelding.com/صرف عام معلومات جي مقصدن لاءِ آهي. سائيٽ تي سڀ معلومات نيڪ نيتي سان مهيا ڪئي وئي آهي، جڏهن ته، اسان سائيٽ تي ڪنهن به معلومات جي درستگي، ڪافي، صحيحيت، اعتبار، دستيابي يا مڪمل ٿيڻ جي حوالي سان ڪنهن به قسم جي، ظاهري يا ضمني نمائندگي يا وارنٽي نٿا ڏيون. ڪنهن به صورت ۾ سائيٽ جي استعمال يا سائيٽ تي مهيا ڪيل ڪنهن به معلومات تي ڀروسو جي نتيجي ۾ ڪنهن به قسم جي نقصان يا نقصان لاءِ اسان توهان جي ڪنهن به قسم جي ذميواري نه کڻنداسين. سائيٽ جو توهان جو استعمال ۽ سائيٽ تي ڪنهن به معلومات تي توهان جو ڀروسو صرف توهان جي پنهنجي خطري تي آهي.

پوسٽ جو وقت: مئي-24-2024